The Philosophy of Zero Defects Is:

In practice l to 2 defects is acceptable. In practice 1 to 2 defects is acceptable.

Zero Defects In Quality Management Zqc Analysis Plan Example

In practice 1 to 2 defects is acceptable.

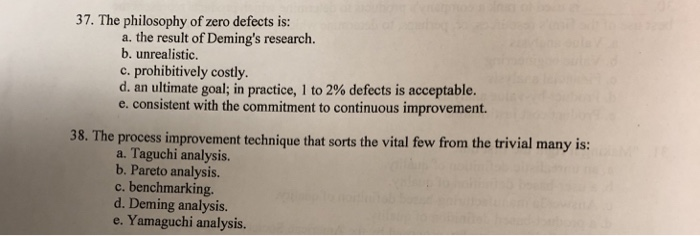

. The process improvement technique that sorts the vital few from the trivial many is. Zero defects is a philosophy not just a way of fabricating items. It doesnt have distinct steps to follow or rules to abide by which leaves companies open to customizing how they want it to work for themselves.

The result of Demings research. The pros and cons of Zero Defects. D an ultimate goal.

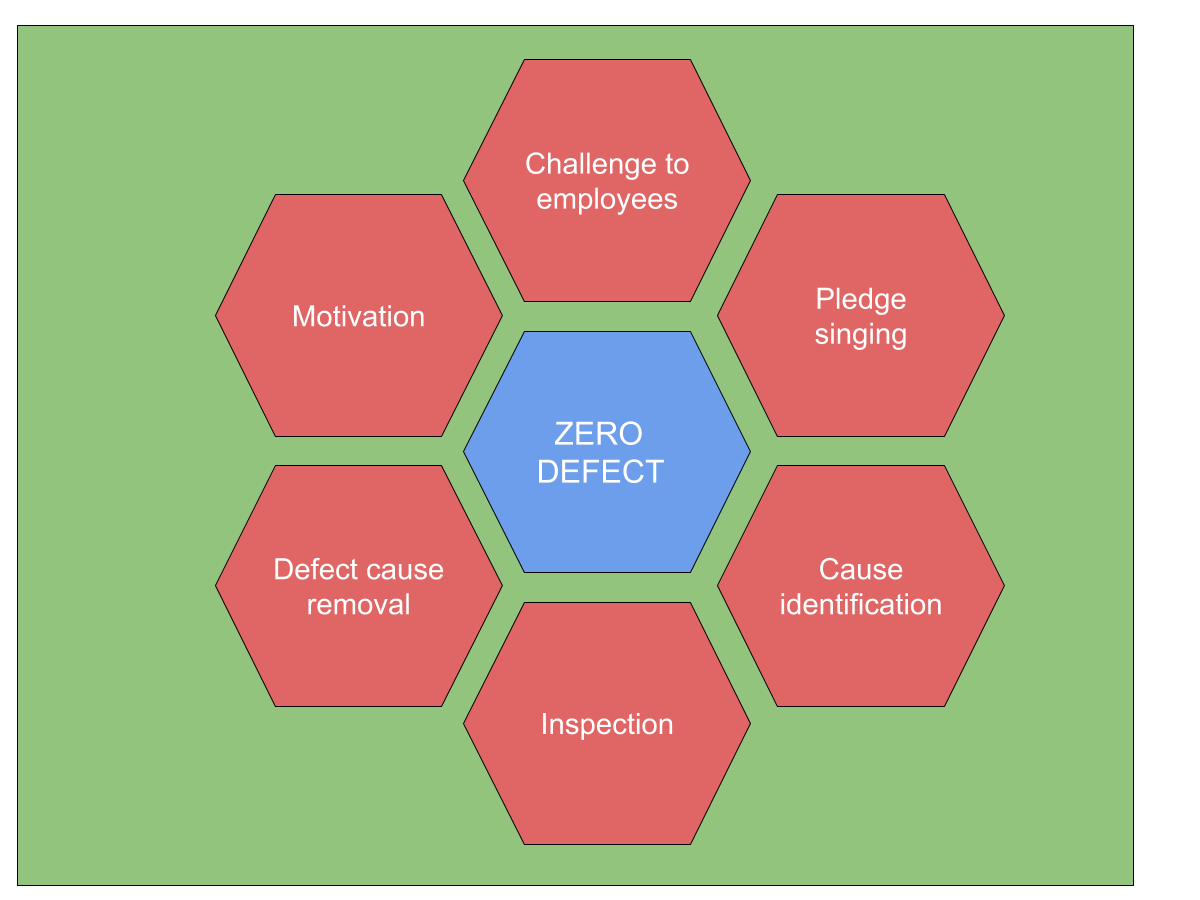

Zero defects is referred to as a philosophy a mentality or a movement that aims to minimize the number of defects in manufactured products and service as much as possible. Waste refers to all unproductive processes tools employees and so on. Zero Defects is the approach to quality that was developed and promoted by the guru Philip B.

Zero defects is a way of thinking and doing that reinforces the notion that defects are not acceptable and that everyone should do things right the first time The idea here is that with a philosophy of zero defects you can increase profits by eliminating the cost of failure and increasing revenues through increased customer satisfaction. Unrealistic prohibitively costly an ultimate goal. Zero Defects is referred to as a philosophy a mentality or a movement.

The philosophy of zero defects is. Ask questions directly from Qualified Online Accounting Tutors. Prohibitively costly C.

In practice 1 to 2 defects is acceptable. Zero defects theory ensures that there is no waste existing in a project. The Principles of Zero Defects.

The Philosophy Of Zero Defects Is. He called for companies to adopt the new philosophy. An ultimate goal in practice 1 to 2 defects is acceptable.

Book a demo Try it for free Zero defects is a philosophy that reinforces the notion that mistakes are not acceptable thereby saving you time and money. Consistent with the commitment to continuous improvement. Consistent with the commitment to continuous improvement.

It does not have distinct steps or rules to follow. An ultimate goal in practice 1 to 2 defects is acceptable O B. The philosophy of zero defects is Learn Accounting.

It aims to minimize the number of defects in manufactured products and services as much as possible. View the full answer. The philosophy of Zero defects is _____.

An Ultimate Goal In Practice 1 To 2 Defects Is Acceptable. He philosophy of zero defects is A. The ultimate aim of the.

Correct option is D Was this answer helpful. Consistent with the commitment to continuous improvement. The result of Demings research b.

Zero Defects is a Lean philosophy a mentality or a movement introduced by Philip Crosby that aims to reduce and minimize the number of defects and errors in a process in hopes of getting things done right the first time. The philosophy of zero defects is. Study the philosophy of zero defects and how it can save you time and money.

In other words this is a commitment from the company to its customers that all. The result of Demings research. Common with the zero defects theory is the concept of doing it right the first time to avoid costly and time-consuming fixes later in the project management process.

The philosophy of zero defects is. Consistent with the commitment to. Zero Defects was a management-led program to eliminate defects in industrial production that enjoyed brief popularity in American industry from 1964 to the early 1970s.

A zero defect-philosophy for products made from natural resources is not entirely possible and implies constructive contributions on each level of production and manufacturing to. This philosophy is really a mentality or movement as it has no defined set of steps or rules to follow. In practice 1 to 2 defects is acceptable e.

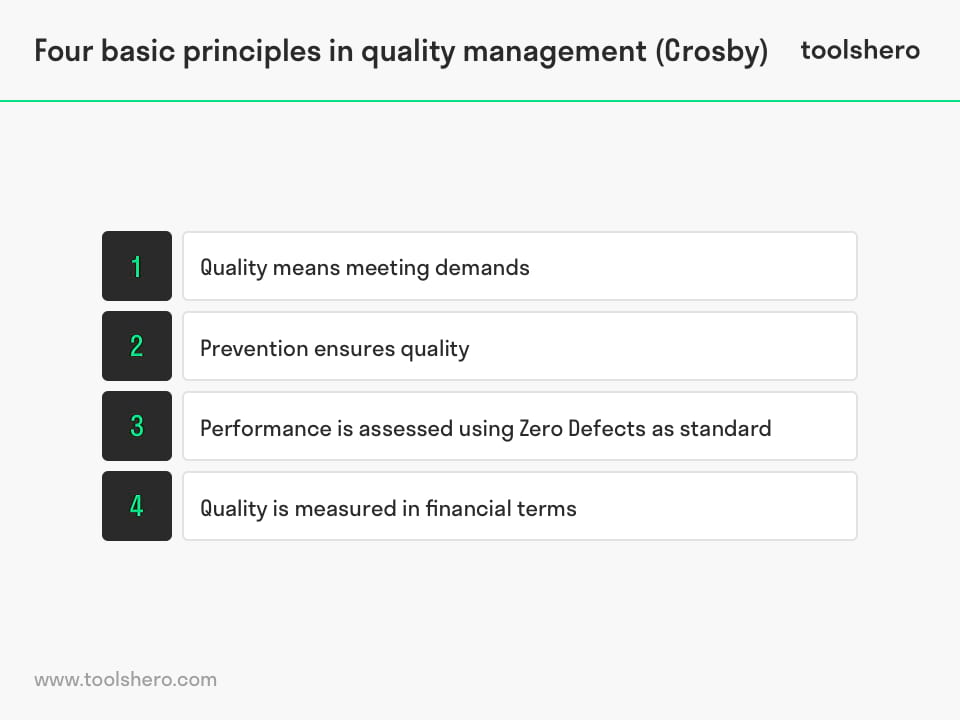

Consistent with the commitment to continuous improvement. Quality expert Philip Crosby later incorporated it into his Absolutes of Quality Management and it enjoyed a renaissance in the American automobile industryas a performance goal more than as a. A the result of Demings research.

The philosophy of zero defects is a. Zero Defect Plan also known as the zero-defect program is an organizational philosophy that aims to reduce the number of defects in new products or processes. Zero Defects was first introduced by American businessman Philip Crosby in his 14 Step Quality Improvement Process.

Its a way of thinking about quality that doesnt tolerate errors or defects and continually strives to improve processes and prevent errors so that work is always. Fortunately todays innovations like Artificial Intelligence and Machine Learning can help organizations improve their products quality while reducing if not eliminating defects. Consistent With The Commitment To Continuous Improvement.

While all 14 principles are related to it lets look at the first four principles summarized by the Deming Institute. E The Result Of Demings Research. E consistent with the commitment to continuous improvement.

The aim of zero defects is to mimimize the number of defects in manufactured products and service as much as possible and relies on each company to. Implementation is divided into these two categories. Edward Deming captured the necessary change in mindset in the 14 principles laid out in a book published in 1982.

Best for online homework assistance. Zero Defect Manufacturing Implementation. The philosophy of zero defects is.

Forget Six Sigma this is Infinite Sigma. D an ultimate goal. The result of Demings research.

Consistent with the commitment to continuous improvement. Crosby in his book Quality Is Free.

Solved 37 The Philosophy Of Zero Defects Is A The Result Chegg Com

No comments for "The Philosophy of Zero Defects Is:"

Post a Comment